Are you over 21?

units filled at our breweries

largest brewer in the U.S.

total square feet between our manufacturing facilities

Our breweries are the largest and most technologically advanced facilities built in the United States in the last 20 years. This capability and scale provides us with strategic advantage, allowing us to react quickly to trends in the industry and meet the growing and changing needs of our customers.

Our warehouse is highly automated from the dock doors to our robotic Laser Guided Vehicles (LGVs). Working in tandem with our highly skilled warehouse teams, our fleet of LGVs and automation platform ensures efficient storage, fast delivery times, and optimized outbound shipments to our distribution partners.

Through our commitment to sustainability, we invested over $20 million into building full-service railyards at our Columbia, SC and Glendale, AZ breweries. One railcar of raw material is the equivalent of four tanker trucks. By reducing the number of trucks on the road, we greatly reduce emissions and the environmental impact in producing our products.

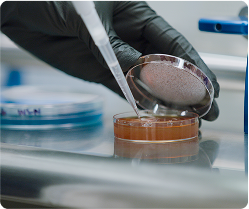

We invested over $5 million into building highly sophisticated laboratories that are foundational to our unrelenting commitment to quality. No expense was spared to outfit the labs with the latest state of the art analytical equipment. Our highly sophisticated equipment measures key product components such as carbohydrate levels in order to optimize the fermentation process. Additionally, we have inline instruments that constantly test our liquid streams for critical components like alcohol and Carbon Dioxide. Our quality lab also analyzes certain flavor components including potential defects which can include visual, aromatic, and taste deficiencies. There are over 800 quality checks that are executed on each case of product before being sent to consumers

The packaging lines have the flexibility to pack cans into single flavor cartons or trays & into variety packs. The lines have the capability to fill various can sizes and can fill 12oz cans at a speed of 1,500 cans per minute or 90,000 per hour. Additionally, each brewery has a unique system in place to create the variety packs onsite, improving the freshness and speed to market of our products. In Glendale, AZ, we have a fully automated system where cans can be filled and packaged directly inline. In Columbia, SC and Hillside, NJ, while there is no direct feed from the filler to the packer, the packers still support a highly automated process. The Columbia, SC Variety Pack systems are the fastest Variety Pack lines in the world.

The tank farm is the heart of the brewery, it's here where we conduct our fermentations, store raw material and finished alcohol base. We have over 130 fermentation & liquid tanks.

We have the ability to fabricate parts as needed to minimize downtime and keep our breweries operational. On average our maintenance team performs over 3,000 work orders and preventative maintenance orders each month.

We capture Carbon Dioxide (CO2) during high CO2 production within the fermentation process. The CO2 is then scrubbed and cleaned to 99.99% purity, before being concentrated down to specified levels for use in our products. Over 4000 tons of CO2 we’re recovered in the first 6 months of this new process.

Day in the Life of a Packaging Operator

Apply HereDay in the Life of a Brewing Operator

Apply HereDay in the Life of a Maintenance Technician

Apply HereDay in the Life of a Plant Utility Technician

Apply HereDay in the Life of a Quality Lab Technician

Apply HereDay in the Life of a Shipping & Receiving Clerk

Apply Here