Why Mark Anthony chose Columbia?

This is a press release from Columbia Metropolitan Magazine, originally posted on their website A Brewing Success.

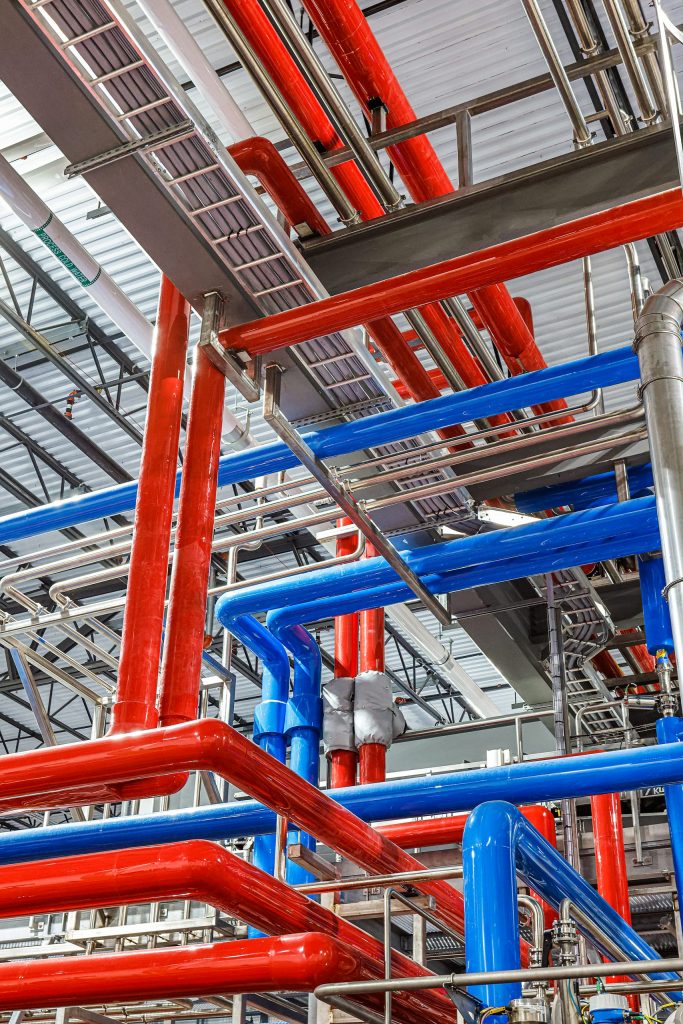

Mark Anthony Brewing invested more than $500 million to build its plant in Columbia. Just 346 days after breaking ground, the first saleable product rolled off the conveyor. The facility has four high speed can lines, one bottle line, and two variety pack lines.

Jennifer McGehee, a beer buyer for Morganelli’s Party Store on Forest Drive in Columbia, has been connecting customers with their favorite alcoholic beverages for nearly a decade. The first hard seltzer she remembers seeing was Truly, from the makers of Samuel Adams beer.

“Then White Claw came in right after that and it just took over,” she says. “I first saw a White Claw that summer; I was literally floating down a river when a friend handed one to me.”

That was in 2017, and by 2019, “White Claw Summer” was proclaimed on social media by hard seltzer aficionados. User-created content reinforced White Claw’s message of a beverage that’s portable for youthful, outdoor fun and not targeted toward a specific gender. Major media outlets took notice.

The Wall Street Journal compared its viral trend power to the pumpkin spice latte. The Atlantic described White Claw as a symbolic response by millennials to years of being told coolness was found in fussy cocktails or complex IPAs. Jennifer says that after she saw her first White Claw, it became practically an instant hit in the Midlands — so much so she doubted its staying power.

“I totally thought seltzers were going to be a flash in the pan,” she says, but now even local craft breweries are concocting their own hard seltzers to have a beer alternative on tap in their tasting rooms. “They’ve become that popular. Seltzer’s not going anywhere. It’s here to stay.”

Somewhere between “flash in the pan” and “here to stay,” a booming company half a continent away began engineering a business pivot. As its plans unfolded, a patch of Midlands turf that had been curated for the right company at the right time met its moment. Now a 1.3-million-square-foot facility on Shop Road is producing can after can of fruity libations for all the White Claw Summers to come.

The logo on a can of White Claw Hard Seltzer depicts three cresting waves, a “white claw” in surfing dialect. The beverage inside hopes to evoke the refreshing spray of a crashing wave. It was introduced in 2016 by The Mark Anthony Group of Companies.

Based in Vancouver, British Columbia, Mark Anthony was founded by Anthony von Mandl in 1972 as a wine importer. It has grown to encompass its own vineyards in addition to producing distilled spirits and ready-to-drink alcoholic beverages. Privately owned, its U.S. family tree includes Mark Anthony Brands, handling sales and marketing, and Chicago-based Mark Anthony Brewing, responsible for supply chain management and brewing.

For years, Mark Anthony Brewing had outsourced production of a beverage portfolio that also features Mike’s Hard Lemonade and Cayman Jack cocktails. As John Sacksteder, Mark Anthony Brewing’s president, explains it, the company relied solely on contract manufacturers to produce its product. The company would install its proprietary and patented equipment within its partners’ facilities, which allowed them to ensure the quality it demanded. Then White Claw took off.

QUOTES

“We were surprised and overwhelmed by the success,”

“We could never have planned for the level of demand we were being asked to produce. Because we did not own our own plants, to increase production capacity, we had no choice but to spend millions of dollars with our co-packers to increase both brewing and packaging capacity.” – John Sacksteder, Mark Anthony Brewing’s president

John Sacksteder, Mark Anthony Brewing’s president

QUOTES

“We are very proud to call Columbia, South Carolina, home. We’re making several million cases per month off the lines in Columbia. We are at 278 employees, and we expect we’ll be running full-out somewhere around 325. From a national perspective, we’re meeting demand, and now we have room to grow.”– John Sacksteder, Mark Anthony Brewing’s president

Mark Anthony Brewing invested more than $500 million to build its plant in Columbia. Just 346 days after breaking ground, the first saleable product rolled off the conveyor. The facility has four high speed can lines, one bottle line, and two variety pack lines.

At that point, Mark Anthony Brewing decided to take matters into its own hands. A company that likes to move quickly, in November 2019, it began construction of a new brewery and packaging operation in Hillside, New Jersey. By January 2020, it had also broken ground on its most ambitious project yet, a nearly one-million square-foot facility in Glendale, Arizona. The Hillside project took 202 days, John says. Glendale took 280.

QUOTES

“It’s something we think nobody else could have pulled off,” John says, and it is particularly true of Glendale, which began as an undeveloped greenfield site. “What made both of these projects even more challenging was that in March of that year, the world shut down due to COVID. We never stopped construction and found ways to work as safely as possible through this unprecedented challenge. But we never could fully satisfy the demand.”– John Sacksteder, Mark Anthony Brewing’s president

Another facility was needed — fast. A Mark Anthony Brewing task force came up with 18 locations in five states, then narrowed the list to 10 and made site visits. Columbia was not at the top of the list.

The Social Media Insights Lab at the University of South Carolina examined more than 400,000 social media mentions related to “spiked seltzer” going back to the start of 2019. Its findings noted some surges in activity during the summers of 2020 and 2021 and the past three Super Bowls. A lot of the activity was being driven by marketing heavyweight Bud Light, which created a spike, so to speak, when it unveiled its own seltzer in late 2019. The biggest surge, however, went back to August 2019 and the peak of White Claw Summer, when young adults, social influencers, and media outlets began posting on Instagram, tweeting, and writing articles about hard seltzer.

In many ways, the hard seltzer market came of age right along with millennials and Generation Z. Fruit-flavored sparkling water gained popularity as those two groups grew up. Parents equated fruit with healthiness and saw it as a way to get their kids to drink water instead of more sugary options.

Brands such as Izze, LaCroix, and Sparking Ice grew, and plenty of generic, one-liter bottles are available at the supermarket. It’s little wonder the berry, watermelon, and mango flavors these kids were raised on now headline hard seltzers.

QUOTES

“Today’s young adult drinkers (those of legal drinking age to 27 years old) grew up with fruity drinks, including Capri Sun and other juice boxes,” writes Boris Oglesby in a blog for data analysis firm IRI Worldwide. “They’re carrying that taste for sweet, fruity products with them as they age.”

While many number-crunchers see the market as a zero-sum game — every hard seltzer drinker is a former drinker of something else — it may be more appropriate to recognize hard seltzer drinkers as new entrants to the world of alcoholic beverages. Many, upon turning 21, adopted White Claw as their first drink of choice and not a replacement for something else.

Mark Anthony Brands has grown to become the fourth largest beer company in the United States in terms of sales. Technically, it is considered a beer company. Fermented sugar forms the products’ alcohol base, so hard seltzers and lemonades are sometimes referred to as “malternatives.”

White Claw varieties are gluten free, contain 5 percent alcohol by volume, and weigh in at 100 calories. Most beer contains gluten, to which some people have an immune reaction and which others avoid for dietary reasons. White Claw’s alcohol content is slightly higher than popular light beers and the calorie count sits between 96-calorie Miller Lite and 102-calorie Coors Light.

Those factors satisfied multiple consumer trends, fueling the White Claw boom. John estimates White Claw’s market share of the seltzer category exceeds 47 percent, with the next closest competitor in the mid-20s. He’s proud of what the product has as well as what it doesn’t — a beery, malty smell or aftertaste.

QUOTES

“The taste is clean and pure,” he says. “What White Claw does is give flavor; we’re a flavor company. We believe we make the best alcohol base in the industry. We’ve spent 20 years in R&D perfecting this process.” – John Sacksteder, Mark Anthony Brewing’s president

They didn’t have that much time to build their next brewery, however. Economic developers often say a site’s infrastructure makes the difference between attracting industry and missing out. That was no different in this case.

QUOTES

“They needed a bunch of power — fast,” says Jeff Ruble, economic development director for Richland County. “We ended up running a rail spur to their site. We’re blessed with a ton of water capacity. They’re using 3 million gallons of water a day, and 2.5 million goes back into the wastewater stream.” – Jeff Ruble, economic development director for Richland County

Columbia’s water capacity was critical in attracting Mark Anthony Brewing. The plant uses 3 million gallons of water each day.

Several years ago, Richland County acquired land to create the 1,000-acre Pineview Industrial Park. A multi-phase extension of Shop Road connects the park to Interstate 77. Jushi USA, a fiberglass manufacturing plant, was the park’s most prominent resident, but plenty of room remained for a neighbor.

QUOTES

“We had done all the homework and had the perfect site for them,” Jeff says. “In the past we would have been passed right over. It’s the difference between winning and losing.” – Jeff Ruble, economic development director for Richland County

One of the most crucial aspects was the timely delivery of an electrical transformer capable of handling the plant’s needs. Dominion Energy doesn’t necessarily have those $500,000 units laying around in a lot somewhere. It begat a chicken-and-egg question of whether Dominion Energy would commit to buying the unit if Mark Anthony Brewing would commit to the site, or vice versa.

QUOTES

“Sometimes you have to live on faith and not live on fear. We made a decision to go ahead and purchase that transformer,” says Keller Kissam, president of Dominion Energy South Carolina. He jokes that with his neck on the line for the purchase, he told the Mark Anthony Brewing representatives he would “hunt them down” if they backed out. “We also had to build a tap off our transmission line. We also had to build a gas line.” – Keller Kissam, president of Dominion Energy South Carolina.

Keller praises the linemen, gas journeymen, electricians, and other Dominion Energy employees who got the work done during the pandemic. John appreciates the commitment Dominion Energy made. In fact, he credits the willingness of the community to adopt Mark Anthony Brewing’s sense of urgency as the ultimate reason Columbia won out.

QUOTES

“From the governor to the county to the utilities, they would work at our pace to help keep the project on time,” John says. “We had tremendous support from the county, from permitting to the inspectors coming out on weekends to help keep us on time. The energy was contagious. We invested more than $500 million to build this plant. Not every community was prepared for something like that. Some communities checked a couple of the boxes but not all of them. Columbia ended up having all the boxes checked, and they brought the commitment to work with us, at our pace.” – John Sacksteder, Mark Anthony Brewing’s president

Richland County acquired land several years ago to create the 1,000-acre Pineview Industrial Park. Mark Anthony’s building is 1.3 million square feet with 40 acres of dedicated parklands. A multi-phase extension of Shop Road connects the park to Interstate 77. Photography courtesy of Mark Laven.

Speed proved to be a virtue in other ways. They were able to purchase necessary steel before pandemic-related supply chain shortages afflicted the construction industry. Just 346 days after breaking ground, the first saleable product rolled off the conveyor.

QUOTES

“It feels good. We are very proud to call Columbia, South Carolina, home. We’re still ramping up the production lines,” John says. “We’re making several million cases per month off the lines in Columbia. We are at 278 employees, and we expect we’ll be running full-out somewhere around 325. From a national perspective, we’re meeting demand and now we have room to grow.” – John Sacksteder, Mark Anthony Brewing’s president

John says an adjacent parcel of 40 acres is available if they need to expand. Some of the facility’s footprint has been dedicated to a park with walking trails for employees. They’ve also planted 200 trees as part of a commitment to sustainability.

QUOTES

“Operating in a sustainable way is critical to us. We have installed a state-of-the-art CO2 recovery system, which allows us to capture the CO2 created during the fermentation process, clean it, and then reuse it in our production process,” John says. Many ingredients are delivered by rail instead of truck. “For every rail car that comes in, that’s five tanker trucks taken off the road, and we bring hundreds of rail cars per year into the plant. We built a facility in the plant that’s focused on recycling waste streams. Our brewing process is unique and requires much less water than a traditional beer brewery would; however, we do create waste water. In order to be efficient and a good partner with the city of Columbia, we also added a $15 million wastewater treatment plant on site, which cleans the water before it goes to the city.” – John Sacksteder, Mark Anthony Brewing’s president

Keller remembers meeting with Mark Anthony Brewing representatives under a tent due to the pandemic. He was introduced to them through his role with the Central SC Alliance, a public-private economic development group serving the Midlands.

“It’s important that existing industry folks participate in the economic development process,” Keller says. While copious amounts of data are available, companies comparing communities for a new project want to know what it’s really like to do business there. “If you can take that and relay it and confirm it to a prospect, it really makes a difference.”

According to California-based Grand View Research, the global hard seltzer market was valued at $8.95 billion in 2021. It expects the market to expand at a compound annual growth rate of 22.9 percent from 2022-30. Even if the growth wave mellows, there appears to be plenty of fizz remaining to keep the Columbia production lines moving and seltzer drinkers tweeting.